Manufacture of Japan's first segmented mirror telescope using world's-first super high precision, high speed grinding technology.

[Joint project of University of Kyoto, University of Nagoya, and the National Astronomical Observatory]

Provided by Nagase Integrex Co., Ltd.

Provided by Nagase Integrex Co., Ltd.

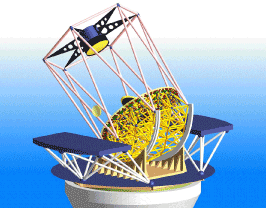

Nano-Optonics Energy supported the technologies used to create this 3.8m diameter astronomical telescope, which is installed at the National Astronomical Observatory in Okayama. In particular, it would have been impossible to make the mirror that is the most important part of the telescope without our super high precision, high speed grinding machines.

This telescope is installed on Mt. Chikurinji (elevation: 372m) in Kamogata-cho, Asakuchi City located in the southwestern part of Okayama Prefecture.

--Telescope Specifications

Diameter: 3.8m (mirror with 18 panel segments)

Type: Ritchey-Chretien

Focal point: Nasmyth focal point × 2

Field of vision: 1° (visible)

Image quality: 80% within an angle of 0.5 seconds

Japan's first segmented mirror telescope

As the basic technology of next-generation, super large telescopes, the segmented mirror will be the most common type in the future. A single mirror has been used in conventional telescopes such as the Subaru Telescope (8.2m diameter). In contrast, this telescope aligns its segmented mirrors with nano-level precision so they function as a single mirror.

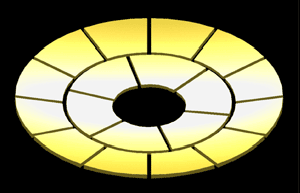

18 segmented mirrors are combined to form a single mirror

(illustration; gaps are exaggerated).

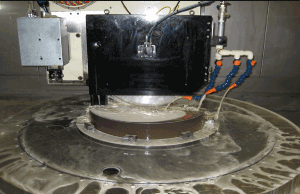

The world's first segmented mirror made by grinding

Nano-Optonics Energy used the ultra-precision, large grinding machine N2C-1300D from Nagase Integrex Co., Ltd., which is installed at Nano-Optonics Research Center (Seki City in Gifu Prefecture), to make the 18 segmented mirrors to shape-precision of 0.2μm and surface roughness of 10nm or less. It also has an automatic polishing function that maintains the shape.

The N2C-1300D, a large grinding machine that boasts super-high precision.

We used a grinding method which, unlike conventional grinding methods, can make large mirrors in a short time (grinding with a file whose position is precisely controlled).

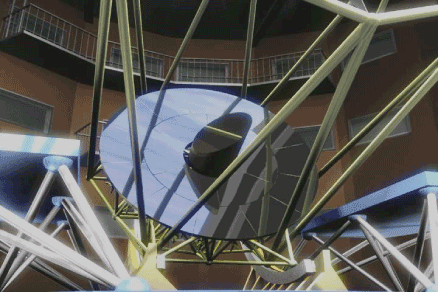

World's first truss structure drive system

Thanks to a truss structure that is placed in a triangular shape on the back of the telescope, it was possible to create a light, sturdy telescope.

This technology can be applied to large telescopes in the 30m diameter class. The large light concentration capacity and high resolution (light quantity 13 times and resolution 3.6 times of those of the Subaru) large telescope planned by the California Institute of Technology will be made using this 3.8m telescope grinding method and the segmented mirror method.

When the 30m-class telescope is completed, it will be capable of:

- Searching for newly formed black holes

- Observation of the first formation of stars in space

- Observing the shape of planets outside the solar system

- Searching for traces of life on planets